Electronics Production – Electronic Manufacturing Services (EMS)

Our services

- Electronic Manufacturing Services / EMS

- Contract PCB assembly

- Surface mounting (SMT)

- Hand mounting (THT)

- Procurement of components

- Material management

- Quality assurance & testing

- Coating and sealing

- Potting and injection moulding

- Single pieces

- Pilot runs (0-series)

- Small series

- Middle size series

- Mass production

Accurate, a Precise Fit and Perfect – Electronics Production at AMS

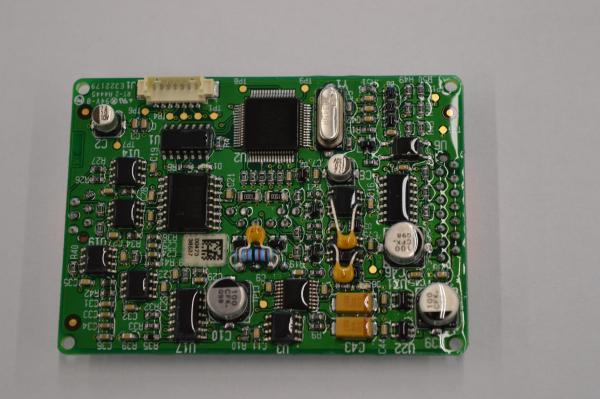

The mounted circuit board, the heart of any electronic product, not only needs to be intelligently designed but also produced to a perfect quality. In our company, that task is assumed by our skilled production and assembly teams, supported by engineers who follow both the development and the production process.

Electronic Manufacturing Services (EMS)

The production process may either be part of a complex systems solution for our customer or part of a special sub-area.

For naturally, we also offer mounting of circuit boards as a modular component.

Further information related to EMS: //Electronic Manufacturing Services (EMS)

Surface mounting (Surface-mounted device)

Automatic SMT is the core of our state of the art production facilities. //Surface mounting

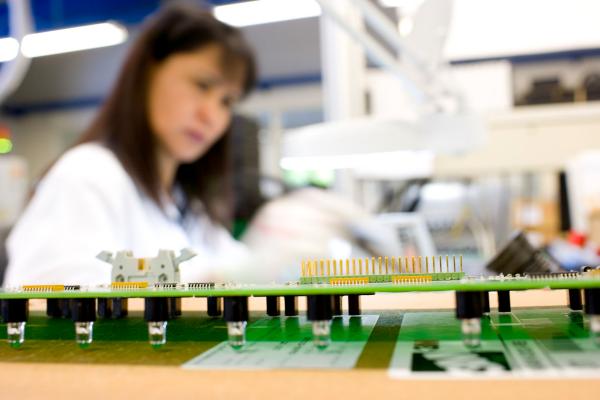

Hand mounting (Through Hole Technology, THT)

But in those areas where machines cannot replace the human eye, our experienced manual assemblers make sure we meet our quality requirements. //Hand mounting

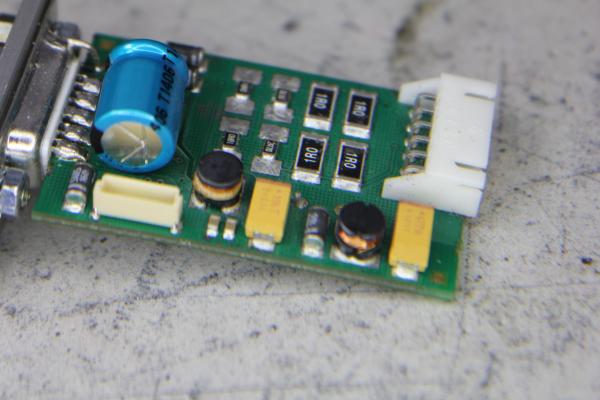

Quality testing

As part of quality testing, all circuit boards pass through our strict final testing systems, which examine the components for completeness, position and polarity. In addition, our unified labelling system for individual components guarantees that each part can be reliably traced (traceability). //Traceability

Quality deserves a long life – and optimal way protection

For ensuring a particularly long durability – especially with regard to sensitive components – we offer special sealing (surface sealing, coating), potting, injection moulding and beyond coating of the finalized circuit boards. For doing so, we rely on special silicones as well as insulating and protective paints. We kindly advise you. //Contact

Last but not least

Pleasurely – if desired – we deliver our quality-tested final products to you in packaging suitable for end customers – or directly to your customers. //Logistics

Related content

Surface Mounting

With our state of the art manufacturing plant we at AMS surface mount circuit boards in our SMT assembly. Automatic SMT is the core of our production facilities – operated and monitored by our experienced employees. Take a look into our production facilities:

High Quality Circuit Boards Hand Mounting

There are just some things which a human can do better than a machine. The employees in our assembly teams further refine circuit boards through hand mounting (THT) by operating with solder waves and at selective soldering units. With completely steady hands and an eye for detail. Take a look into our assembly: