Range of services – Electronic Manufacturing Services (EMS) from AMS

What is the range of services of Electronic Manufacturing Services (EMS)?

The range of services offered by EMS is broad - and interdisciplinary.

It is not limited to the pure production/manufacturing (i.e. the manufacture) of electronics in the form of PCB assembly (SMD assembly, manual assembly (THT), BGA assembly).

EMS range from the initial idea for an electronic product to the final tested, packed and delivered to the (end) customer -

and, depending on requirements, includes all intermediate steps of development, component procurement and storage, production, assembly, quality assurance and testing, packaging, logistics (including material logistics) and more.

Here it is important to select from the possible services those that the customer needs.

We provide you with an overview.

Range of services of Electronic Manufacturing Services (EMS) in the context of electronics manufacturing and production

As a manufacturing service provider, EMS produce electronic components and assemblies - from the manufacture of the printed circuit boards themselves or their procurement, through their assembly in the context of PCB assembly (machine assembly on automatic assembly machines, SMT, manual assembly (THT, Through Hole Technology) and BGA assembly) to quality assurance and testing.

Depending on the requirements and needs, the production is concluded with a casting or protective coating.

EMS also program the programmable devices (controllers/integrated circuits, ICs) installed on the finished electronic assemblies using the software provided for this purpose.

Further information is available here: //Electronics

EMS services in the context of electronics manufacturing and production

The services of EMS accompanying or related to production/manufacturing are on the one hand the concrete production planning together with the customer (specifications and agreements regarding the selection of manufacturers and suppliers, components and assemblies to be used (parts lists), order volume, time of production, the capacities to be used and more).

Furthermore the material management and material logistics (material procurement, material provided by customers, etc.), the specification and procurement of exactly fitting housings, etc.

Range of services of Electronic Manufacturing Services (EMS) in the context of electronics and device assembly

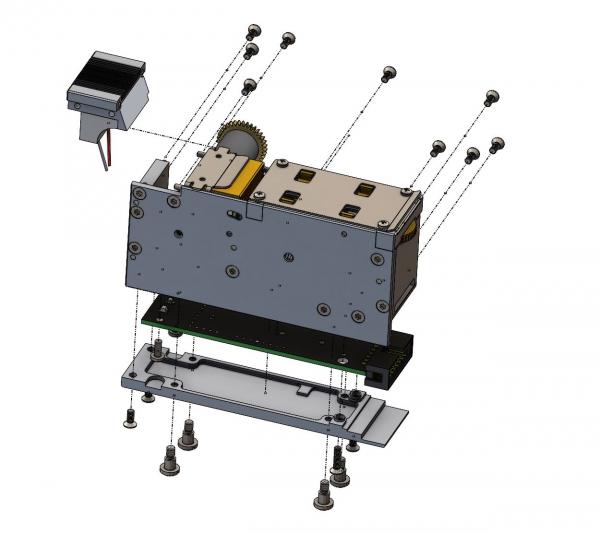

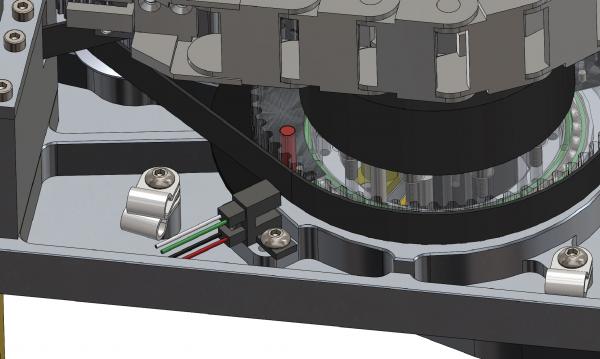

In order for a fully functional product to be created from manufactured electronic components and assemblies, further electronics or device assembly is required. EMS assemble the self-made or supplied components and assemblies so that they come together to form the finished product.

You can find further information here: //Assembly

Range of services of Electronic Manufacturing Services (EMS) in the context of electronics development and design

Further services of EMS are the development and design of electronics.

These range from circuit design, PCB layout, computer-aided simulation to functional samples (proof of concept) and fully functional electronic prototypes (prototyping).

It does not always have to be new developments, but EMS development services can also relate to the redesign / retrofit of existing electronic solutions.

The development of electronics includes not only the hardware development itself, but also the development of software that provides or enables the desired functionalities (software development). Thus, within the scope of software development, firmware development and finally the programming of embedded systems, the functionalities are developed and delivered, which are finally provided by the finished product.

Further information is available here: //Electronics development

Range of services of Electronic Manufacturing Services (EMS) in the context of product ideas and development projects

Within the framework of product ideas and development projects, EMS offer comprehensive services from the concretization of product ideas to requirements analysis and conceptual design, feasibility studies, consulting activities and assume key roles in projects.

Further information is available here: //Project planning and project implementation

Range of services of Electronic Manufacturing Services (EMS) in the context of quality assurance and testing

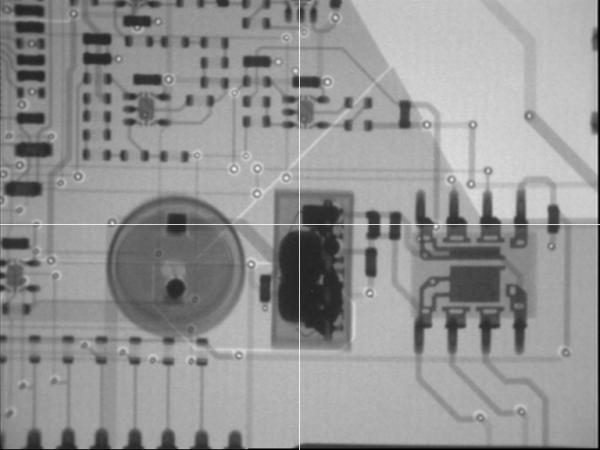

In addition, EMS services include the implementation of quality assurance measures and tests. These are either carried out as part of production/manufacturing as part of the range of services of the production order or are individually determined in type and scope by agreement.

By default, tests are carried out for a sample defined according to the scope of production, although other procedures can be agreed individually, e.g. periodic samples or a routine test (each product).

A multitude of different test procedures can be applied, e.g. Automated Optical Inspection (AOI), Flying Probe Tests (FPT), In-Circuit Tests (ICT), X-ray tests, functional tests and many more.

EMS also cover the development of test procedures and test concepts/test designs, whereby the transitions to development are fluid if special test adapters and test systems are developed for this purpose. If test systems - e.g. for functional tests - are already available, it is not uncommon for them to be provided by the customer.

The labeling of manufactured components and assemblies enables complete traceability of manufactured products even after production.

Further information is available here: //Quality, test procedures and traceability

EMS services in the context of logistics management

In the context of logistics management, EMS packs the finished products - if necessary in packaging suitable for the end customer - and sends them to the customer or directly to his end customer. Nationally and worldwide.

Furthermore, EMS take over the material logistics in the context of production.

You can find further information here: //Logistics

Range of services of Electronic Manufacturing Services (EMS) in the context of further services

EMS offer a variety of other services, such as obsolescence management. The transition of these services begins with the selection of manufacturers and suppliers and the components and assemblies to be used, but also includes the monitoring of component discontinuations, the transmission of corresponding information to customers, the storage of components in stock, the continuous quality monitoring of these stocks and much more.

In this context, it is important that EMSs carry out the selection of manufacturers and suppliers in a targeted manner and that components or assemblies are consciously selected as early as the production planning stage. However, if a component is discontinued, it is important to react adequately - and, for example, to make a decision for a last order (last time buy) - and thus ensure smooth further production. If necessary, suitable alternatives that do not require a costly redesign of the electronics must also be found.

Further services in our in-house mechanics department

Our own in-house mechanical department enables us to provide additional services in the design and manufacture of mechanical components and assemblies beyond the actual range of services offered by Electronic Manufacturing Services (EMS). Services that complement our EMS portfolio perfectly - and offer our customers real added value.

Further information is available here: //Mechanics