High Quality Circuit Boards Hand Mounting

Our services

- Hand mounting (THT)

- Final mounting

- Cable assembly

- Packaging

- Quality assurance and final inspection and testing

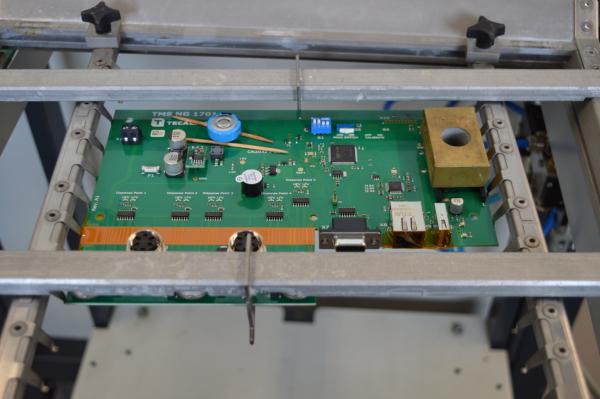

Obsessed with Detail and Nimble-Fingered – Hand Mounting at AMS

After surface mounting´s completion

About 80 percent of the circuit boards we manufacture require manual finishing after automatic mounting. There are just some things which a human can do better than a machine.

Further refinement

The employees in our assembly teams have an eye for detail. With completely steady hands and 100 percent concentration they operate with solder waves and at selective soldering units – until every itty-bitty detail fits.

After final mounting they carry out cable assembly and within component assembly they are responsible for ensuring the final devices are correctly mounted when delivered.

Quality testing

Quality plays a major role – also in hand mounting. Therefore we perform strict and profound testing procedures, which we regularly develop dedicated testing systems for by ourselves. You will find an overview on our testing procedures here //Quality

Packaging & Logistics

Finally quality-assured and securely packaged, we send the finished assemblies and products to a destination of your choice – even neutrally packed directly to your customer. For more information, see //Logistics