We are Experts in Surface Mounting Located in Schleswig-Holstein, Germany

Our services

- Surface mounting (SMT)

- Ball grid arrays surface mount

- Competitive prices

- Reflow soldering process

- Vapour phase soldering process

- up to 170.000 components per hour

- Component range: 0,1 x 0,1 mm to 50 x 150 mm

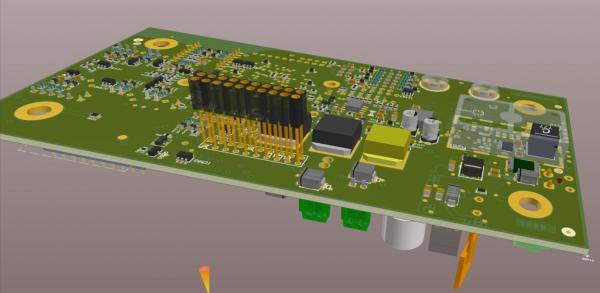

From Sample Quantities and Pilot Runs to Mass Production – Surface Mounting at AMS

With our state of the art manufacturing plant (Siemens, Juki) we are able to mount circuit boards individually or in mass production (surface mounted device).

Our mounting capacity ranges up to 71.000 components per hour. Through this our production capabilities range from sample quantities to mass production – with a wide component range (0,1 x 0,1 to 50 x 150 mm).

Optimum soldering process guarantees first-class quality

In the soldering phases we use the following two different processes: Reflow soldering process and vapour phase soldering process.

By choosing the optimum process in each case we can guarantee first-class quality.

Flexible production flows

Thanks to our flexible production flows we are able to meet individual customer requests at short notice.

By doing so, we enable short leadtimes and meet even very specific requirements.

Quality testing

Quality plays a major role – also in SMD mounting. By using different testing methods during the production process and in our strict final quality assurance, we guarantee that errors are recognized early and ultimately completely eliminated. You will find an overview on our testing procedures here. //Quality

Excited?

Are you as enthusiastic as our longstanding customers and we are? Don´t hesitate to contact us. //Contact