Rapid Prototyping – modern prototype development & production at AMS

Rapid prototyping for agile product development

At AMS we not only produce electrical prototypes, but also physical prototypes in the form of tangible models.

In this way, we can initially model and test entire systems and technical solutions in a prototypical manner, while keeping a firm eye on future series production during all stages of prototype development and prototype production.

A modern method of prototype development and production that we use is "Rapid prototyping".

What is meant by Rapid Prototyping (RP)?

Rapid Prototyping (RP) is a process that enables the rapid production of prototypes in the sense of sample components or physical models.

Consequently, it describes as "rapid prototyping" a new, agile and innovative development and production process (prototype development/prototype production).

In the context of product development – to which rapid prototyping usually refers – it is sometimes also referred to as rapid product development (RPD) .

What is the technical procedure for Rapid Prototyping (RP)?

Rapid Prototyping differs in its approach from other manufacturing processes such as machining, where layers of material are removed (subtractive manufacturing processes, cutting).

Rapid prototyping is a generative manufacturing process, which is more like a primary forming process. In this process, a workpiece (i.e. a three-dimensional object) is created in which a large number of material layers are applied on top of each other (layer application). To make this possible, shapeless or neutral materials are used, whereby physical or chemical effects are used.

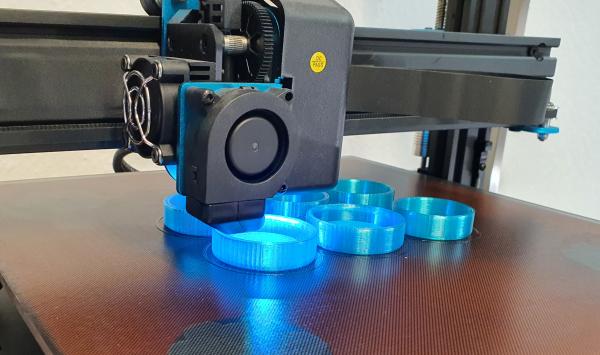

A typical and frequently used process in rapid prototyping is 3D printing.

Due to the described procedure, in the context of rapid technologies we also speak of additive manufacturing (AM) or generative manufacturing.

What is the practical approach to Rapid Prototyping (RP)?

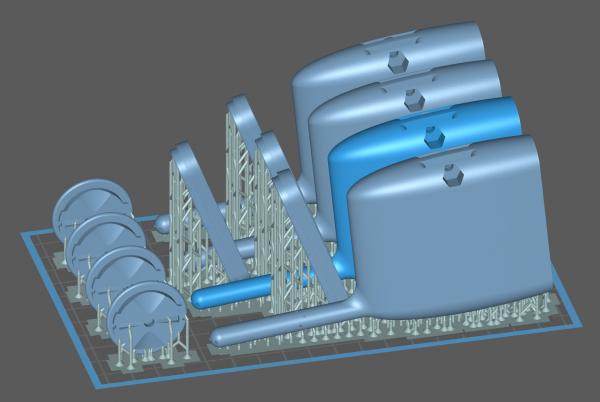

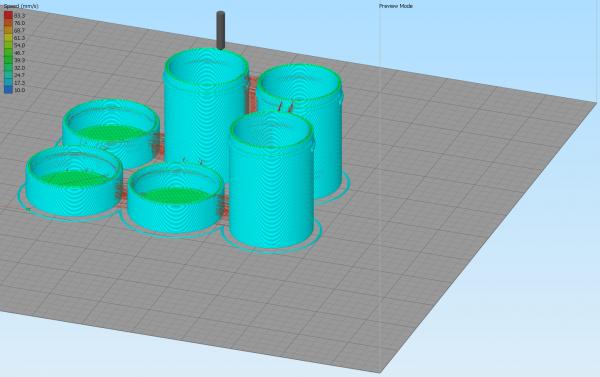

In order to use the manufacturing process of rapid prototyping, a complete volume description of the workpiece to be manufactured is required first. In a first step, the workpiece must be designed as a 3D model using special CAD software (computer-aided design).

After the construction by means of CAD, rapid prototyping aims to convert the existing model quickly and directly into a physical model, i.e. an actual workpiece. In this way, a modelled prototype can be produced for the first time as a single piece – or in small quantities – within a few hours.

What are the advantages of Rapid Prototyping (RP)?

The spatial capacity of the human imagination is limited. As the complexity of one or more interconnected objects increases, the limits of the imagination are quickly reached. Furthermore, real interrelationships and the interaction of several components can often only be made "tangible" – and really testable – with physical models.

This is where Rapid Prototyping (RP) comes in and enables a product idea, for example, to be made tangible quickly in product development, where it can be tested quickly and specifically (aspects of tangibility and testability).

In comparison with and in contrast to other manufacturing processes and in particular the subtractive processes (cutting) – especially machining – 3D printing shows an increasing economic efficiency with increasing complexity of the component geometry and/or lower required quantities. The latter property means that the manufacturing process described is particularly suitable for rapid prototyping and has specific, low costs.

Which methods of Rapid Prototyping (RP) are used at AMS?

At AMS we use the methods of Fused Deposition Modeling (FDM) (melt layering) and Stereolithography (SL/ SLA) (application of light-curing plastics).

Rapid prototyping thus represents a sensible supplement to our conventional mechanical production methods – and leads to considerable time and cost advantages in prototype construction.